Imagine my excitement when I found out the DOE’s, 2020 U.S. Lighting Market Characterization report had been released! This is the forth in a series that attempts to understand the United States consumption of lighting and its commensurate energy use. While I was unaware of the initial 2001 report, by 2012, (the publication date of the 2010 findings) I was deeply enmeshed in energy efficient lighting. That report, along with the oddly named 2012 DOE study, Residential Lighting End-Use Consumption Study: Estimation Framework and Initial Estimates, were heralded as benchmarks of data for their comprehensive approach to understanding where we were in the lighting/energy consumption space. The 2015 report (published in 2017) helped the energy efficient lighting industry see what they had accomplished in five years. Now, ten years after the industry started to take efficient lighting seriously, solid results of a decade of blood, sweat and tears can be shown. In short, this is good news, but there is also more work that can and will be done.

History

Let’s assume you’re not like me (lucky you!) and you have not waited with bated breath for this report. Let’s also assume, you didn’t even know about the three previous editions. That’s OK. That’s why you read this blog. I’ll happily slog through a 70 page government document and extract the valuable nuggets of information. Before I do that, let me give you some background information.

Because of the importance in reduced energy consumption, the US government became involved in a number of energy saving efforts over the years. Adopting the “lowest hanging fruit” parameters, items like refrigeration, industrial motors, AC units and appliances were pushed toward greater efficiency through a combination of incentives and mandates. By the time I became involved in energy efficient lighting, they had reach better, almost optimal performance. Lighting was the “next big thing.” At the time, lighting consumed almost 15% of the typical residential consumer’s expenditure on electricity, bested only by room temperature conditioning. If nothing were done, that number was calculated to reach an incredible 45%, while other equipment became more and more efficient. To determine if the efforts were working, they needed information that no one had. How many light bulbs/luminaires are there in the US? Where are they? What type are they and how much electricity do they really consume? By creating the first, but more importantly, the 2010 report, a baseline was established. This report told us how many lights we had, how much power they consumed and how they were used. To this day, it is information I use regularly.

People will often question the need of government agencies. This information, available to all, is one of the many great reasons.

What Can We Learn From This Report?

There is an installed inventory of 8.1 billion lighting products (light bulbs and/or integrated luminaires.) This represents a 5% increase in residential, but a reduction in commercial lighting when compared with the 2015 report. That commercial reductions is attributed to multi-lamp linear fluorescent troffers being replaced with integrated LED units. Residential units account for an astounding 6.5 billion.

| 2010 | 2015 | 2020 | |

| Residential | 5.812 billion | 6.219 billion | 6.506 billion |

| Commercial | 2.069 billion | 2.076 billion | 1.643 billion |

| Total | 7.881 billion | 8.295 billion | 8.149 billion |

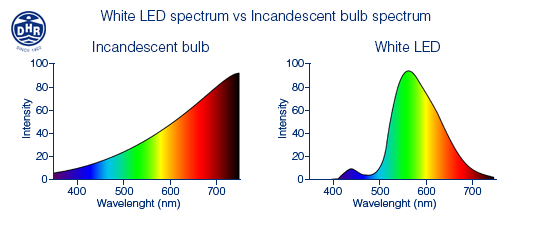

LED has made tremendous inroads in use. LED represented only 1% in the 2010 report, 8% in 2015 and now is responsible for almost 48% of all light sources in 2020. We can assume it to be even larger today, four years after the data collection.

| Lamp Type | 2020 Percentage of Installed Units |

| Incandescent | 12.6% |

| Halogen | 6.6% |

| CFLs | 24.6% |

| Linear Fluorescent | 8.2% |

| HID | 0.1% |

| LED | 47.6% |

| Other | 0.3% |

| Miscellaneous | 0.3% |

Reviewing the installed percentages helps us see that there are a LOT of CFLs still in place, as America’s first foray into energy efficiency. At 12.8% the tiny amount of incandescent is encouraging. I guess it means that the people who were hording light bulbs represented a lot less than were reported.

As a note, I continue to remain skeptical of the fairly large percentage of linear fluorescent used in the home. I raised this point with the DOE in 2012 and still need convincing. If we dig deeper into my concerns, the next tranche of data adds additional fuel to my fire of doubt.

The data below indicates the average quantity of installed units per 1000 sq. ft. I have expanded the LED section so you can see those details. I think they are telling as well.

If we think about an average 2000 sq. ft. home, we’ll need to double these numbers and I believe a lot of this makes sense. Incandescent lamps have burned out and have been replaced, first with CFLs and then later with LED. Because they are longer lasting than the incandescent they replaced, many are still in service.

| Lamp Type | 2020 Average Number of Installed Units per 1000 sq. ft. of Building Space |

| Incandescent | 6.5 |

| Halogen | 3.4 |

| CFLs | 12.7 |

| Linear Fluorescent | 4.2 |

| HID | 0 / negligible |

| LED – Total | 24.5 |

| General Service “A” | 14.1 |

| General Service “Decorative” | 3.5 |

| Integrated LED Luminaire | 1.2 |

| Linear | 0.2 |

| Reflector | 5.5 |

| Miscellaneous LED | 0.1 |

| Other / Miscellaneous | 0.36 |

Here also, I think you can see my concern with the linear fluorescent number. 8 ½ linear fluorescent lamps seems high. I guess a 2000 sq. ft. home could have two shop lights and a 2’-0” x 4’-0” fluorescent in the kitchen, but it seems a stretch, especially because this means EVERY home in America must have this amount. That means many people have MORE! This just does not add up.

I’m also suspicious of the LED integrated luminaires and the reflector numbers. I wonder if there is some confusion with integrated recessed units and retrofit recessed PAR & R lamps. This might just be a transition year, but with integrated recessed, integrated under cabinet lighting, integrated utility lighting, LED integrated into bathroom mirrors, 2 ½ integrated LED luminaires per 2000 sq. ft. home seems low.

The distribution of installed wattage is also telling.

| Lamp Type | 2020 Percentage of Installed Wattage |

| Incandescent | 32.7% |

| Halogen | 15.9% |

| CFLs | 17.3% |

| Linear Fluorescent | 14.7% |

| HID | 0.1% |

| LED | 18.8% |

| Other | 0.4% |

| Miscellaneous | 0.4% |

The installed wattage lets us know that incandescent still consumes 32.7% of our energy for lighting. The good news is that the next highest number is LED at 18.8%, then CFLs at 17.3%. Halogen is 4th at 15.9%, so that means almost half (48.6%) of our energy for lighting is still servicing non-efficient light! There is huge room for more reduction.

The average TOTAL wattage of the installed units has gone down to 21.6 watts in residential installations and down to 26.6 in commercial use.

Also interesting is the daily operating hours of lighting per room.

| Room | 2020 Average Daily Operating Hours |

| Basement/Crawlspace | 1.4 |

| Bathroom | 1.2 |

| Bedroom | 1.1 |

| Closet | 1.4 |

| Dining Room | 1.5 |

| Exterior | 3.1 |

| Garage | 1.2 |

| Hall/Stair/Entry | 0.7 |

| Kitchen | 2.5 |

| Living Room / Den | 1.6 |

| Office | 1.7 |

| Utility Room | 1.4 |

| Other | 1.4 |

| Unknown | 1.6 |

| Average Overall | 1.6 |

As with past surveys, the exterior lighting is used for the longest period of time each day, followed by the kitchen. This is no surprise, except the hours is even higher for exterior lighting than in surveys of the past, meaning we are using outdoor lighting more than ever. Offices are now #3 beating out living rooms, probably because of the increase in “Work from Home” activity, although this is pre-pandemic 2020 data. If this is a trend, expect to see it even higher in the next survey.

The use of controls were also measured for effectiveness. I’m only showing residential use here as commercial use of controls is radically different and much more effective.

| No Control | Dimmer | Day- lighting | Occu-pancy Sensor | Timer | EMS | Multi |

| 89% | 9% | 0% | 0% | 0% | 0% | 1% |

Controls were only considered if they showed the ability to reduce wattage consumption. Based on their collection of data, 89% of the lighting used in residences is not operated with a control that can reduce energy consumption. (Think of this as the number using a simple on-off switch.) That means, the placement of energy-reducing controls per room is surprisingly low. Dimmers are the most popular and they are most used in dining rooms and living rooms, as expected. Occupancy sensors have some use, again low, primarily in garages, closets, utility rooms and exterior locations.

This is why we are seeing such a push for controls as the next step in reduced energy consumption. They have the capacity to reduce energy almost without impact to the user, but we are not seeing much movement yet, even with the mandates established by California Title 24. I had expected to see a slightly higher adoption here.

Power Consumption is also covered extensively. Remember, the whole goal of the efficiency push in lighting was to reduce overall energy use. Overall power consumption of electricity for residential and commercial lighting is 244 TWh. Overall, lighting consumes 9% of all electricity used. The data below shows the huge reductions delivered since the 2010 report.

| 2010 | 2015 | 2020 | |

| Residential | 175 TWh | 148 TWh | 76 TWh |

| Commercial | 349 TWh | 237 TWh | 168 TWh |

| Total | 524 TWh | 386 TWh | 244 TWh |

Residential lighting represents 80% of the installed base but consumes only 76 TWh or 31% of the total. Conversely, commercial lighting is only 20% of the installed units, but consume 69% of the total.

Digging deeper into the data we see clearly why the change to LED was so important.

- 2010

- 78% of electricity for residential lighting was consumed by incandescent

- 2015

- 42% of electricity for residential lighting was consumed by incandescent

- 2% of electricity for residential lighting was consumed by LED

- 2020

- 28% of electricity for lighting was consumed by incandescent

- 20% of electricity for lighting was consumed by LED

In ten years the energy consumed for lighting moved from 78% to 48%. That is quite an achievement. All you lighting people out there have earned a cookie!

As you might imagine, this report is rich with information. If you are inclined to read the whole thing, please do so. It’s a page-turner! https://www.energy.gov/eere/ssl/articles/2020-us-lighting-market-characterization

The companion piece, Residential Lighting End-Use Consumption Study: Estimation Framework and Initial Estimates can be found here: https://www1.eere.energy.gov/buildings/publications/pdfs/ssl/2012_residential-lighting-study.pdf

(Remember, this was foundational 2012 data and should be used to understand the history and where we were at that point. Nonetheless, some of the stats found in this report are still considered valid and used in the calculations of the new 2020 data.)

If you elect to forgo the entire report, I hope this was a good overview that will help you plan energy efficient actions into the future, or at the very least, provide a “pat on the back” for your past hard work.